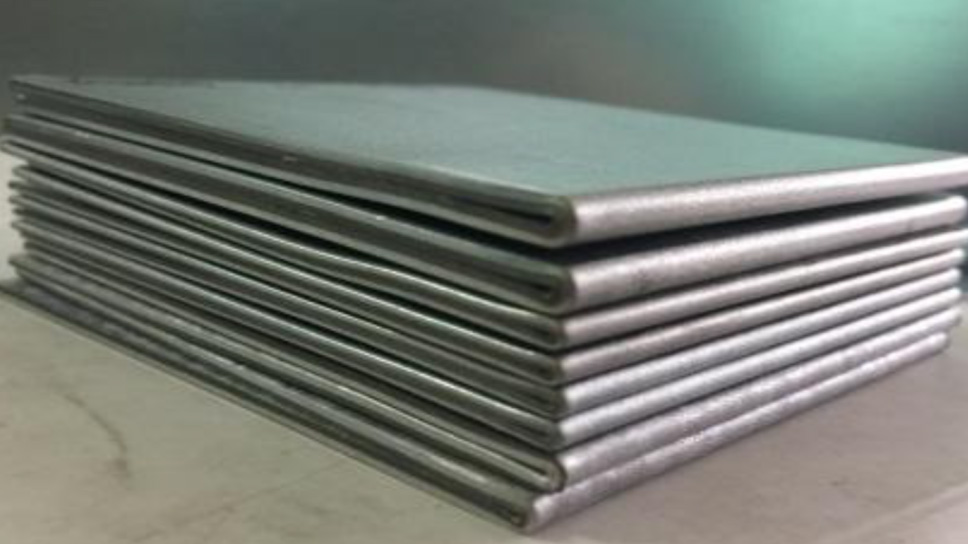

What is Al Zn Mg Steel Plate (band)?

Zinc-aluminum-magnesium is a kind of alloy metal, mainly used for surface anti-corrosion treatment of steel and steel products, including various zinc series coatings and a large number of whole steel parts immersion-plated anti-corrosion, initially used as surface anti-corrosion of steel products .

The metal processed is pure zinc. With the improvement of technology, alloy metals such as aluminum-zinc alloy and zinc-aluminum-magnesium alloy have appeared one after another, which increases the corrosion resistance of the metal layer.

Hapmetal super corrosion-resistant zinc-aluminum-magnesium alloy coated steel sheet (strip) is formed by high temperature solidification of zinc (Zn), aluminum (Al), magnesium (Mg) and other rare elements on the surface of the steel plate (strip) using special advanced technology. Eutectic structures such as Zn, Al, Zn2Mg, etc., penetrate the steel base and form a firm bonding surface with the steel base, which prevents corrosion of the steel strip; the surface of the zinc (Zn)-based coating containing magnesium (Mg) will form dense protection Layer, and play the role of anti-corrosion and self-repairing of steel belt.

PRODUCT PERFORMANCE

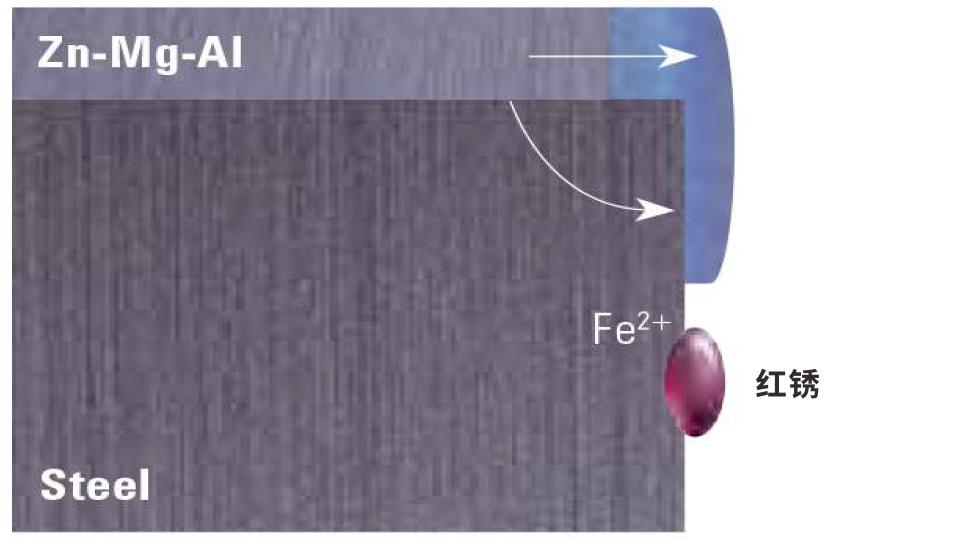

- Super corrosion resistant:The samples of Wuxi City Product Quality Supervision and Inspection Institute conducted salt spray test. The galvanized steel strip showed red rust after 384 hours, while the super corrosion-resistant zinc-aluminum-magnesium alloy coated steel strip did not see red rust after 1000 hours. Compared with ordinary galvanized products, it can achieve better corrosion resistance, which is 3 to 5 times that of hot-dip galvanized steel.

Super corrosion resistance: Salt spray test

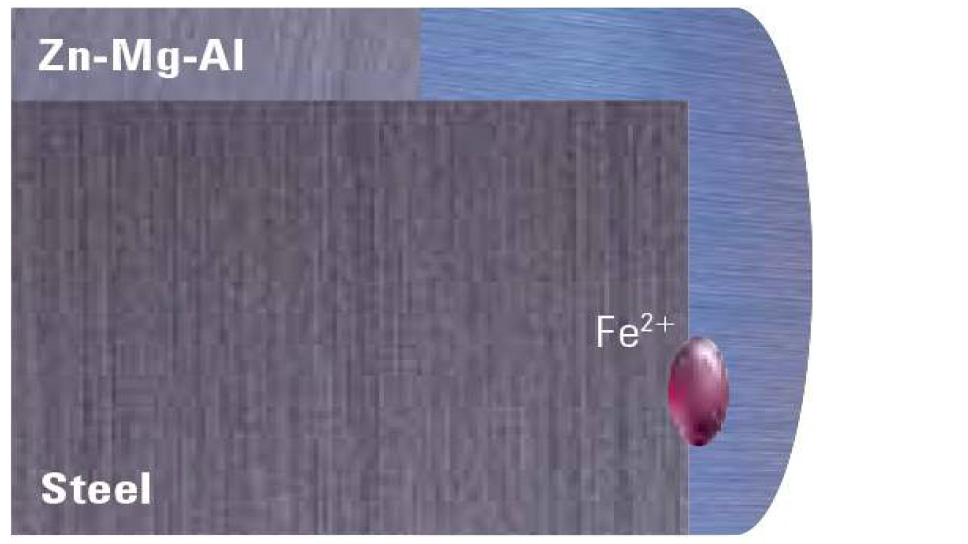

- self-healing:The coating components around the cutting surface and the punching surface can automatically dissolve out and form a dense protective film to cover the cut end surface, incision and embroidered parts, realizing automatic repair of the alloy coating.

Self-healing function: cut or end face

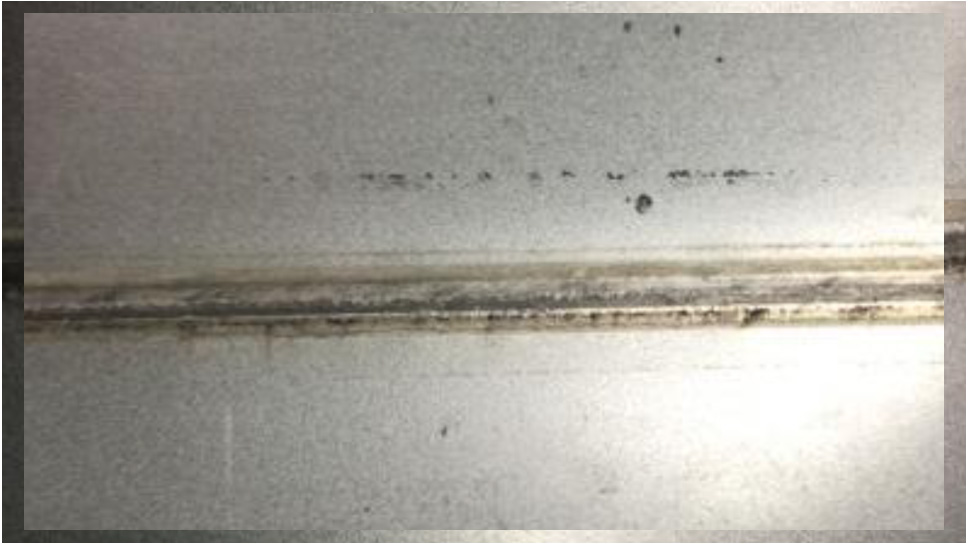

- Zinc-free:The ultra-corrosion-resistant zinc-aluminum-magnesium alloy coated steel plate (strip) has no spangles, and the surface coating is dense and flat, which is beneficial for subsequent personalized processing and advanced coating after the plate (strip) is formed.

Zinc-free–easy welding process

- strong attachment:The coating of hot-dip galvanized aluminum-magnesium steel is denser than that of galvanized steel, so it is not easy to peel off the coating during the stamping process. It has excellent tensile, stamping, bending, welding and other processing properties under severe conditions, and due to the coating The hardness is high, so it has excellent damage resistance.

Strong attachment:Bending test

Strong attachment:Complex bending test

- environmental protection:This product adopts the ecological water washing method to remove rust, and realizes the green and safe environmental protection production process. The product coating does not contain heavy metal elements such as lead, which realizes the safety and environmental protection of the product application field.

Product category

| Classification | Category | Symbol |

| According to processing performance | General performance | PT |

| structure | JG | |

| According to the weight of zinc aluminum magnesium alloy | 001 | |

| 100 | ||

| 200 | ||

| 275 | ||

| 360 | ||

| 450 | ||

| By surface structure | Zinc-free | F |

| Quality by table | Ⅰ | |

| Ⅱ | ||

Product size and shape

| Name | Nominal size (mm) |

| Thickness | 0.8-4.5 |

| Width | 250-760 |

| Roll inner diameter | 400-610 |

Allowable deviation of product width

| Nominal thickness (mm) | Width tolerance | ||||

| ≥ | < | <125 | ≥125 | ≥250 | ≥400 |

| <250 | <400 | <760 | |||

| 0.80 | 1.75 | +0.7 | +1.0 | +1.5 | +2.0 |

| 0 | 0 | 0 | 0 | ||

| 1.75 | 2.50 | +1.0 | +1.3 | +1.7 | +2.0 |

| 0 | 0 | 0 | 0 | ||

| 2.50 | 3.50 | +1.2 | +1.5 | +2.0 | +2.3 |

| 0 | 0 | 0 | 0 | ||

| 3.50 | 4.50 | +1.5 | +1.8 | +2.3 | +2.5 |

| 0 | 0 | 0 | 0 | ||

Allowable deviation of product thickness

| minal width (mm) | Thickness tolerance (mm) | |||||||||

| Nominal thickness (mm) | ||||||||||

| 0.80 | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | 3.00 | 3.50 | 4.00 | 4.50 | |

| ≤250 | ±0.05 | ±0.06 | ±0.07 | ±0.09 | ±0.12 | ±0.14 | ±0.16 | ±0.18 | ±0.19 | ±0.20 |

| >250-≤450 | ±0.06 | ±0.07 | ±0.08 | ±0.10 | ±0.13 | ±0.15 | ±0.17 | ±0.19 | ±0.20 | ±0.21 |

| >450-≤760 | ±0.07 | ±0.08 | ±0.09 | ±0.11 | ±0.14 | ±0.16 | ±0.18 | ±0.20 | ±0.21 | ±0.22 |

Product coating alloy layer weight

| Type of coating | Meets the | The average value of the three-point experiment (both sides) is not less than (g/㎡) | Lowest value of three-point experiment | |

| Double-sided (g/㎡) | Single side (g/㎡) | |||

| Aluminum zinc alloy | 001 | – | – | – |

| 100 | 100 | 89 | 35 | |

| 200 | 200 | 170 | 70 | |

| 275 | 275 | 240 | 95 | |

| 350 | 350 | 300 | 120 | |

| 450 | 450 | 390 | 160 | |

Product corrosion resistance comparison

| t time (h) | Corrosion resistance test of super corrosion-resistant zinc-aluminum-magnesium alloy coated steel sheet (strip) | Corrosion resistance test of galvanized strip | |||||||

| Symbol | Symbol | ||||||||

| 24 | 1 | 100 | 200 | 275 | 350 | 450 | 100 | 200 | 275 |

| 48 | – | √ | √ | √ | √ | √ | √ | √ | √ |

| 72 | – | √ | √ | √ | √ | √ | √ | √ | √ |

| 96 | – | √ | √ | √ | √ | √ | √ | √ | √ |

| 144 | – | √ | √ | √ | √ | √ | × | √ | √ |

| 168 | – | √ | √ | √ | √ | √ | × | √ | √ |

| 240 | – | √ | √ | √ | √ | √ | × | × | √ |

| 480 | – | √ | √ | √ | √ | √ | × | × | × |

| 720 | – | √ | √ | √ | √ | √ | × | × | × |

| 1000 | – | √ | √ | √ | √ | √ | × | × | × |

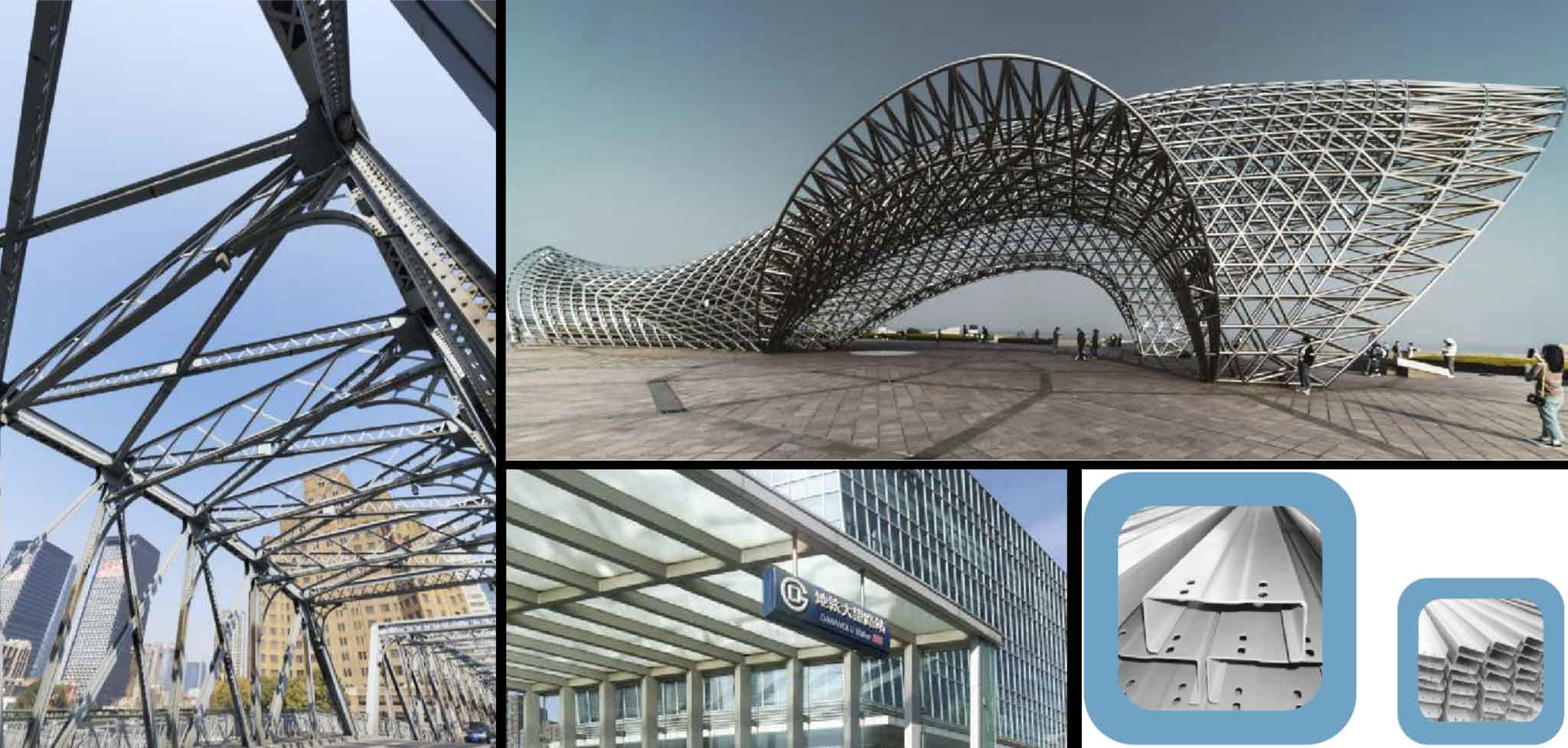

Application

| S/N | Application area | S/N | Application area |

|

01

|

Energy engineering: photovoltaic power station engineering, solar module bracket field | 02 | Underground pipe gallery project: pipelines, media, high and low voltage cables, communication cable trays |

| 03 |

Shipbuilding, marine engineering, etc.

|

04 |

High-speed railway construction field: station buildings, sound barrier structures

|

| 05 |

Highway sound barrier structures, guardrails

|

06 |

Industrial and civil buildings

|

| 07 |

Cable tray, protective fence, household appliances, light steel structure, etc.

|

08 |

Military industry, aviation and other new fields

|

There are no reviews yet.