Summary:

An Effective Method to Extend the Life of Metals: Understanding Corrosion Protection Plates

What is anti-corrosion plate?

The manufacturing process of anti-corrosion plate

Application of anti-corrosion plate

Advantages of anti-corrosion plates

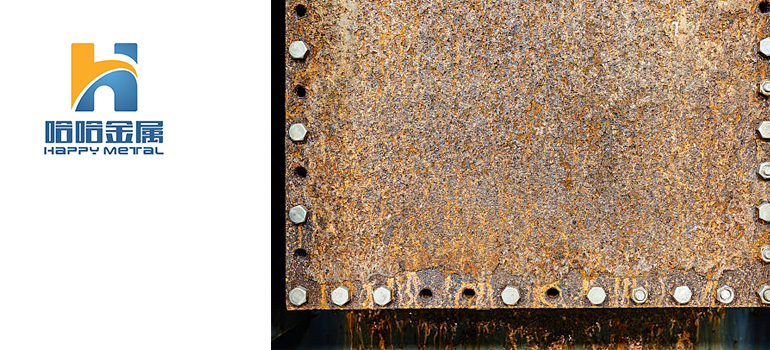

Metal products play a crucial role in the industrial and construction fields. However, metals are susceptible to corrosion when exposed to environmental conditions, which greatly shortens their service life and reduces their performance. To solve this problem, engineers and scientists have developed various anti-corrosion technologies, one of which is anti-corrosion plates. This article will delve into the characteristics, applications, and advantages of anti-corrosion steel plate, helping you understand how to extend the lifespan of metal products.

What is anti-corrosion plate?

Corrosion resistant plate is a special coating or plate coated on a metal surface, aimed at protecting the metal from corrosion and oxidation. These plates can be made of different materials, such as galvanized steel, stainless steel, nickel alloy, etc. The main goal of anti-corrosion plates is to reduce the impact of corrosion factors such as atmosphere, moisture, and chemicals on metals, thereby extending the service life of metal products.

The manufacturing process of anti-corrosion plate

The manufacturing process of anti-corrosion steel plate usually includes the following Committed step:

Surface preparation: Before starting coating, the metal surface must be properly cleaned and pre-treated. This includes removing grease, dust, and other impurities to ensure that the coating can firmly adhere to the metal.

Application coating: According to specific application requirements, use appropriate anti-corrosion coatings or coatings to apply them to metal surfaces. These coatings can be organic, inorganic, or metal coatings, depending on the required level of corrosion protection and working environment.

Curing: After the application of the coating, curing treatment is required. This can be achieved through drying, heat treatment, or chemical reactions to ensure the stability and corrosion resistance of the coating.

Application of anti-corrosion plate

Corrosion resistant plates are widely used in multiple fields, some of which mainly include:

Industrial equipment: many industrial equipment and machinery are exposed to harsh environmental conditions, such as Chemical plant, oil drilling platforms, etc. The use of anti-corrosion plates can extend the service life of these equipment and reduce maintenance costs.

Oil and gas pipelines: Oil and natural gas pipelines often transport corrosive media, and anti-corrosion plates can provide additional protection on their surfaces to prevent pipeline corrosion and leakage.

Marine structures: Metal structures in the marine environment are easily affected by salt mist and humid climates, and the use of anti-corrosion plates can enhance the durability of these structures.

Construction engineering: Metal components in buildings, such as bridges, roofs, and facades, can also use anti-corrosion panels to improve their durability and reduce maintenance.

Advantages of anti-corrosion plates

Extending the lifespan of metals: Corrosion resistant plates can effectively protect metals from corrosion, thereby extending the service life of metal products and reducing replacement and maintenance costs.

Reduce production downtime: The use of anti-corrosion plates can reduce corrosion losses of equipment and machinery, reduce failures and repairs caused by corrosion, and thus reduce production downtime.

Improving safety: Corrosion and metal fatigue may lead to equipment failure and structural damage, which may cause serious accidents. Corrosion resistant plates can improve the safety of equipment and structures, protecting the safety of workers and the public.

Environmentally friendly: Some anti-corrosion coatings and coatings use environmentally friendly materials to help reduce adverse effects on the environment.

Corrosion resistant plates, as an effective metal protection method, play a crucial role in the industrial and construction fields. By applying appropriate anti-corrosion coatings on metal surfaces, the service life of metal products can be extended, maintenance and replacement costs can be reduced, and the safety of equipment and structures can be improved.